October 6, 2023

1663 Resolve™: Custom Cold-Chain Solutions to Eliminate Food Waste

Have you ever arrived home after a trip to the grocery store, only to realize the bundle of bananas you purchased is just a few days away from going bad? Maybe you bought a head of lettuce for a salad, but as soon as you peeled back the top layer, your dinner plans quickly changed.

We’ve all had these experiences as consumers. The act of buying quality produce can be frustrating, tedious, and costly. When a study from the United States Department of Agriculture estimates that produce waste makes up 30-40% of the entire food supply, it begs the question: "What is going on with cold-chain monitoring?”

As it turns out, this issue exists on a much larger scale. Nearly half of the inventory waste takes place at the supply chain level, before the consumer is ever involved. Given the strict industry regulations and the substantial profit loss occurring daily, it’s apparent that existing cold-chain monitoring solutions are in desperate need of a makeover. 1663 Resolve™ was built exactly for this reason.

From Farm to Store

The journey of produce from farm to consumer is a multi-stage process that can be challenging to audit. When a shipment of pears arrives at a supermarket already damaged or spoiled, it can be nearly impossible to determine the cause or party at fault. Existing monitoring solutions in the cold chain industry attempt to mitigate these mistakes; however, these solutions also come with their own headaches.

The primary metric monitored throughout the produce journey is temperature. What should be an easily measurable piece of data becomes complicated when businesses rely on manual data entry or outdated data loggers. When using methods prone to human error, it is no surprise that inventory waste is a common occurrence.

At the same time, companies that strive for more innovative solutions also face their fair share of problems. For many, the costs involved with an automated data collection system far outweigh the benefits. If affordability isn’t an issue, then poor battery life and low range connectivity are two additional hurdles that must be considered.

In the world of produce processing and distribution, each stage is liable for damaged products. If the specific time and place that an order was damaged can be determined, the party at fault is required to compensate the purchaser or replace the product entirely. However, when there are no systems in place to pinpoint who dropped the ball, the costs fall on the buyer.

Searching for a traditional solution in the industry can prove difficult, but luckily there are now more innovative solutions to help companies save on cost and complexity. Enter 1663.

IoT and 1663

While the internet of things (IoT) isn’t a new technology, its growth and utilization in the business world is expanding at a rapid pace. 1663 is an IoT solutions provider built by experts of the Helium Network, the largest public IoT network in the world. Using the vast coverage provided by the Helium ecosystem, 1663 works with large enterprise companies to deliver innovative solutions that enhance the accuracy, reliability, and affordability of their cold monitoring operations.

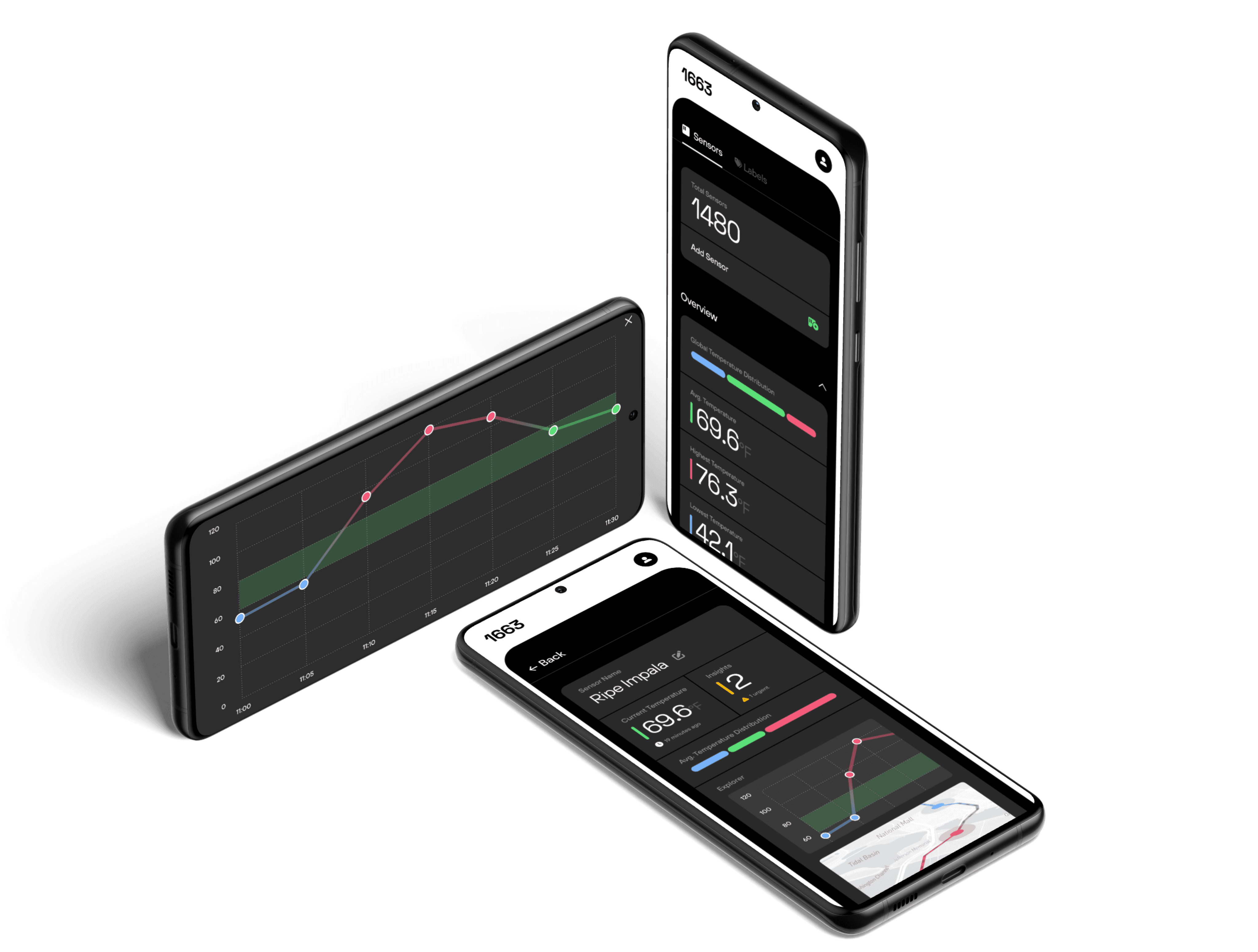

1663 Resolve™, the latest solution from the company, allows grocery stores and other produce buyers the ability to have a custom-developed dashboard based on their specific business needs. Utilizing Resolve, grocery stores and buyers are able to correlate a specific sensor to an exact shipment, allowing for custom alerts that are enabled to immediately notify the proper party if a shipment drops outside of an ideal temperature range. Additionally, Resolve will also make it possible for these businesses to view their entire fleet of sensors quickly, enabling immediate identification of any incidents or temperature deviations during transit.

Contact the Team to Get Started

Want to learn more about how 1663 Resolve can help your business with any cold-chain monitoring needs? Contact the team today for a free consultation.